Prepare making statues

Before Making statue :At work room making the wax models. PLz Go INSIDE to See More PiCtures

Softening a piece of wax over a brazier.

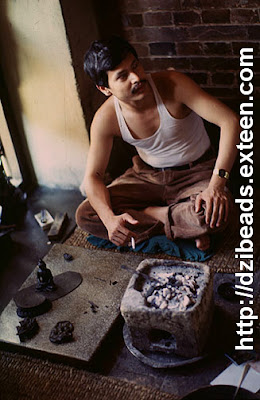

Relaxing after softening the wax The working environment with works in progress.

Relaxing after softening the wax The working environment with works in progress.

Working the face of an Ekajata wax model.

Working the face of an Ekajata wax model.

Working the face of wax model.Using a modeling tool to form the face of Ekajata.

Working the face of wax model.Using a modeling tool to form the face of Ekajata.

Deatail of wax model

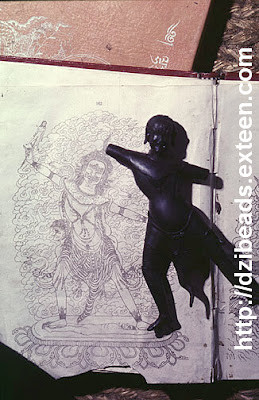

The design for Ekajata compared to the Tibetan book on which it was based.Statues Maker Are master in buddhism .

The design for Ekajata compared to the Tibetan book on which it was based.Statues Maker Are master in buddhism .

Detail of A partially finished Candamaharoshana (Acala) wax figure made in the Tibetan style.

Detail of A partially finished Candamaharoshana (Acala) wax figure made in the Tibetan style.

A finished wax image of Mahakala.

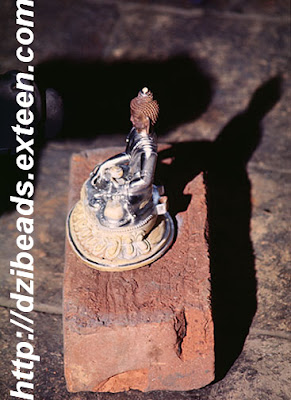

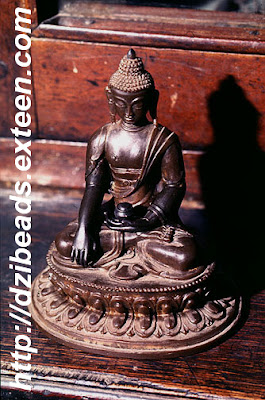

Anthor Finished Wax Model of Shakyamuni Buddha

One of the modelers working in the room shows the Pehar image on which he is working.

The artist showed how the goat , which had been completed earlier, fits under the image. ,

This is first part of making statues After model is ready cover it in a mixture of special clay and cow's dung.

Tej Jyoti Shakya and his wife, Nani Maya Shakya Covering the wax model in a mixture of clay and dung.

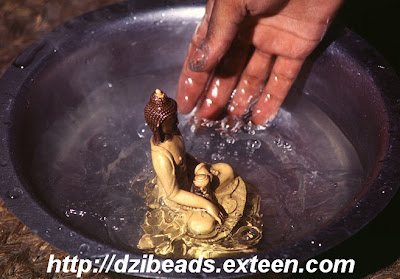

Pressing the mixture of clay and dung around the wax image.

The board with the clay and dung mixture ready for use.

Model Pieces drying after the initial (dipped) thin layer of fine clay.

Model Pieces drying after the initial (dipped) thin layer of fine clay.

Clay-covered model pieces drying in the sun.

Clay-covered model pieces drying in the sun.

This Cover with dungand clay is second part after dry this pcs have to put them in burnig coal. lets see.

Molds waiting to be put into the burnout furnace.

Molds waiting to be put into the burnout furnace. The same molds, seen in the previous image, in the burnout furnace

The same molds, seen in the previous image, in the burnout furnace The double row of refractory bricks used to support the heated molds during casting.

The double row of refractory bricks used to support the heated molds during casting. The melting furnace and a pile of coke used for melting the metals. Laying the bed of coke in the melting furnace.

The melting furnace and a pile of coke used for melting the metals. Laying the bed of coke in the melting furnace. The first ignition of the coke.

The first ignition of the coke. Checking the coke bed.

Checking the coke bed. The electric blower used to force air into the melting furnace

The electric blower used to force air into the melting furnace Beginning to fill the crucibles with scrap copper.

Beginning to fill the crucibles with scrap copper. Preparing the bed of burning coke to receive the crucibles.

Preparing the bed of burning coke to receive the crucibles. Sorting various metals used in the alloys.

Sorting various metals used in the alloys. Weighing precious metals that are used in the alloys

Weighing precious metals that are used in the alloys Weighing copper from Singapore to achieve a correct alloy.

Weighing copper from Singapore to achieve a correct alloy. Different sizes of crucibles and various types of metals to be cast in this melt.

Different sizes of crucibles and various types of metals to be cast in this melt.

Placing the crucibles in the bed of coke filled with metal are in place.

Placing the crucibles in the bed of coke filled with metal are in place. After the crucibles are in place, more coke is piled around them.

After the crucibles are in place, more coke is piled around them. The crucibles are covered with scrap metal to hold in the heat.

The crucibles are covered with scrap metal to hold in the heat. The electric fan is then connected.Soon a very hot flame is produced.

The electric fan is then connected.Soon a very hot flame is produced. The entire furnace temperature goes up to about 1800 -1900 degrees.

The entire furnace temperature goes up to about 1800 -1900 degrees.