Discount Buddhist

To help adjust for the recent dollar price hike and ensure that our customers can continue to enjoy our collection, we are offering a 10% discount on all Buddhist statues and figurines. This special offer is our way of making these sacred pieces more accessible while maintaining the quality and craftsmanship that define our products.

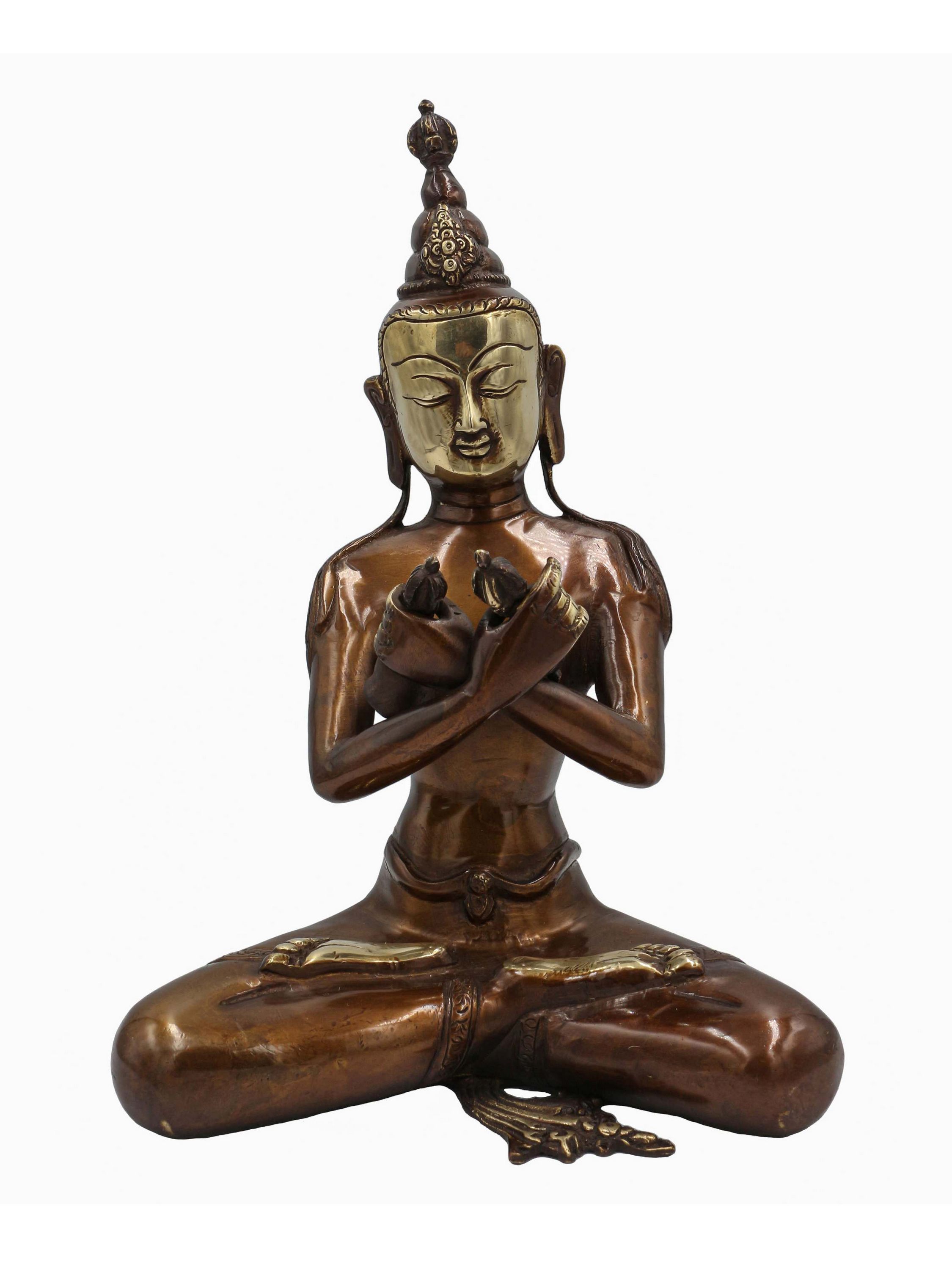

Vajradhara

Shakyamuni Buddha appeared in this world with the sole purpose of benefitting all sentient beings. Out of great compassion Lord Buddha revealed many different means/paths to enlightenment and set forth three Wheels of Law to suit varying degrees of intelligence and receptivities.

Shakyamuni Buddha himself was, it is said, in the form of Vajradhara while he was teaching tantric path to his gifted disciples.

Vajradhara is depicted holding a Vajra and a bell in his left hand and his arms are kept crossed in front of him expressing complete integration of Prajna and Upaya. He is usually depicted in blue colour in vajraparyanka posture. He has a crown, an Urna and an Ushnisha as a Sambhogakaya Buddha. Vajradhara is also depicted in father-mother (Anju-Aji in Newari) aspect. en he holds his usual symbols while his arms are crossed at the back of his consort. the consort is none other than Prajnaparamita in deified form.

The Kargyudpa lineage of Tibetan Buddhism begins with the Buddha Vajradhara. The individual in this tradition is allowed to visualize his root Guru as Buddha Vajradhara. Guru Tilopa is said to have received Mahamudra instruction directly from Buddha Vajradhara through visions and other extraordinary means.

In Nispannayogavali, Vajradhara is the main deity in Vajrasattvamandala. He is three faced, six-armed and reddish white in color. His right arm holds a vajra, a sword and a kapala and his left hand holds a bell, an ankush and a noose. He stands in the Ardhaparyanka posture and dances in Tandava style.

Read More

Brief Introduction

This image represents the understanding & application of internal & external tantric energy, by skilfully influencing & directing energies arising from everyday experiences [Skt. dharmas]. Vajradhara expresses not just the awoken mind but the direction of understanding which develops into a transcendent experience of the Dharmakaya. This is symbolised by the lightening [Skt. vajra] headed bell [Skt. ghanta] which represents the feminine creative wisdom and the double ended lightening sceptre representing 'energy', method & the masculine. Vajradhara personifies the ways [bell] & means [lightening sceptre] to objectively transform experience beyond everyday conception of space & time.

Dharmakaya is often taken to mean the 'truth body' & is one of the three Forms of or realms of understanding [Skt. Trikaya]. The Principle of Non-Duality i.e. the 'union of two' is represented in the Bell [Skt. Ghanta] & the Lightning sceptre [Skt. Vajra]. The bell embodies female wisdom & the Diamond Sceptre being compassion or method. The truth body of Vajradhara and Vajrayana tools will empower your journey in all places. This involves unlocking the mysteries or obscuration's of the material & inner world through methods of tantric practice & understanding. In fact Vajradhara represents latent power of transformation using tantric through wisdom to allow us to uncover Great Bliss. Vajradhara the realised way of method. Since Vajradhara personifies the essence of non dualitic union the figure represents a mastery of the symbols portrayed in other tantric deities & having understood their meaning does not need to bear them.

Iconography

The name Vajradhara means the bearer of the lightning sceptre. The inherent tradition of lightning representing transformation & energy originates 2,500 c. BCE. The term Vajra is a typical Sanskrit word being a composite of va- meaning to bear or carry, ja or ja whose syllable denotes the energy & ra meaning to rise, overcome or power. The vajra sceptre is a special object embodies the principle of change. Conjoined prongs at each end denote lightning bolts and their being conjoined denotes latent self reacting energy. In effect as important to Buddhism as the Cross to Christianity. The Vajra [Tib. Dorje] has four prongs enclosing a fifth central prong making five in total and at both end. The tridents is another representation of the lightening more associated with Hinduism. Varjadhara's arms are crossed in a gesture of Victory over the Three Worlds [Skt. Triolyavijaya mudra also called Skt. Vajrahumkara],with reference to the syllable 'Hum', & is seated in the lotus seat [Skt. Padmasana] The lotus seat & the crossed arms mudra are together called the Skt. Vajrasana or Position of transcendent change. The white sash draped across Vajradharas chest represents the purity and essence of the varjayana school of Buddhism. In fact Mahayana & Hinayana both arise from the ancient Vajrayana tradition of personal transformation.

Commentary

Vajradhara is one of two primeval [Skt. Adi] Buddhas associated with the Trikaya Doctrine. The Sanskrit stem Tri means three & the word Kaya means body in the sense of form. Samantabhadra & Vajradhara, Bodhisattvas & mankind all exist within the primary dimension called Nirmanakaya because have been conceived by the human mind and so in part manifests within time and space. Vajradhara also exists in a second dimension of emptiness realised through the understanding of the emptiness of all phenomena called Dharmakaya. Dharmakaya [Skt.] means Truth Body or Reality Body. Dharmas are phenomena in this universe such as candles, televisions, planets, cows and significantly the laws governing them. The principle of Dharmakaya is that there is no individuality at all as nothing exists on its own and all is transient. The idea is that in fact they are temporary arrangements of emptiness. Thus Dharmakaya is ultimate truth of the unreal nature of all things and that truth is in fact nothing of emptiness. The concept of emptiness helps us break our attachment or dependency on the physical world and free ourselves from cyclical existence.

Dharmakaya represents the inconceivable [Skt. Acintya] aspect of a Buddha out of which Buddhas and indeed all phenomena [Skt. Dharmas] arise and to which they return after their dissolution. The principle of Dharmakaya helps us free ourselves from material bondage & dependency on the material world to take us towards Individual & Universal Bliss which is the union of Great Love and great Freedom. The Five Transcendent Buddhas [Skt. Dhyani Buddhas] arose from the Vajradhara, Adi Buddha,& Samantabhadra. As we detach ourselves we are able to create the Sambhogakaya state of Great Bliss. Some Vajrayana sutras refer to a fourth kaya dimension called Svabhavikiakaya [Skt.] meaning the self created body in the sense of self arising and self perpetuating essence embodying the three other kaya's. This alludes to the self arising self emanating and self perpetuating Thousand Petalled Lotus of Great Bliss.

About Chocolate Oxidized

This Vajradhara has been meticulously treated with a chocolate color antique patina. The intention behind this patina is to replicate the appearance of a copper statue that has gracefully aged over a century. Unlike a simple coat of paint, this patina is not applied superficially and is designed to endure. It undergoes an artificial oxidation process that adds depth and character, while also serving as a protective layer against natural oxidation.

By imitating the natural aging process, the chocolate color antique patina lends an air of authenticity and vintage charm to the Vajradhara. This carefully crafted finish ensures that the patina remains intact for an extended period, offering longevity and resistance to wear. The result is a unique piece that captures the essence of a time-worn copper statue, evoking a sense of history and artistic heritage.

Process: Sand Casting

This Vajradhara has been created using the sand casting system, also known as sand molding casting. This widely employed manufacturing process utilizes a sand mold to produce metal products and components in various sizes and shapes. Sand casting holds significant popularity in the industry, accounting for approximately 60% of all metal castings. The sand casting process involves six primary steps. First, a pattern or replica of the desired sculpture, in this case, Vajradhara, is created using a material like wood or metal. The pattern is then placed in a flask, which is a box-like structure divided into two halves. The next step involves packing the flask tightly with specially formulated molding sand, creating a mold cavity that matches the shape of the pattern. The pattern is subsequently removed, leaving behind a negative impression of the sculpture within the sand mold.

The third step is known as gating and risering, where additional channels and reservoirs are added to the mold to facilitate the flow of molten metal and compensate for any shrinkage during solidification. Once the gating system is prepared, the mold is carefully closed and secured. The fourth step involves pouring the molten metal, such as bronze or iron, into the mold through the gating system. After the metal has cooled and solidified, the mold is broken open, revealing the solid metal sculpture. The final steps involve removing any excess material, surface finishing, and polishing to achieve the desired appearance.

Sand casting offers several advantages, including its versatility in producing complex shapes, cost-effectiveness for both small and large-scale productions, and the ability to use a wide range of metals. However, it does require skilled craftsmanship and careful attention to ensure the quality and accuracy of the final sculpture. By utilizing the sand casting system, the Vajradhara embodies the craftsmanship and artistry of the process, resulting in a captivating and unique metal artwork.

The process cycle for sand casting consists of six main stages, which are explained below

Mold-making -The first step in the sand casting process is to create the mold for the casting. In an expendable mold process, this step must be performed for each casting. A sand mold is formed by packing sand into each half of the mold. The sand is packed around the pattern, which is a replica of the external shape of the casting. When the pattern is removed, the cavity that will form the casting remains. Any internal features of the casting that cannot be formed by the pattern are formed by separate cores which are made of sand prior to the formation of the mold. Further details on mold-making will be described in the next section. The mold-making time includes positioning the pattern, packing the sand, and removing the pattern. The mold-making time is affected by the size of the part, the number of cores, and the type of sand mold. If the mold type requires heating or baking time, the mold-making time is substantially increased. Also, lubrication is often applied to the surfaces of the mold cavity in order to facilitate removal of the casting. The use of a lubricant also improves the flow the metal and can improve the surface finish of the casting. The lubricant that is used is chosen based upon the sand and molten metal temperature.

Clamping - Once the mold has been made, it must be prepared for the molten metal to be poured. The surface of the mold cavity is first lubricated to facilitate the removal of the casting. Then, the cores are positioned and the mold halves are closed and securely clamped together. It is essential that the mold halves remain securely closed to prevent the loss of any material.

Pouring - The molten metal is maintained at a set temperature in a furnace. After the mold has been clamped, the molten metal can be ladled from its holding container in the furnace and poured into the mold. The pouring can be performed manually or by an automated machine. Enough molten metal must be poured to fill the entire cavity and all channels in the mold. The filling time is very short in order to prevent early solidification of any one part of the metal.

Cooling - The molten metal that is poured into the mold will begin to cool and solidify once it enters the cavity. When the entire cavity is filled and the molten metal solidifies, the final shape of the casting is formed. The mold can not be opened until the cooling time has elapsed. The desired cooling time can be estimated based upon the wall thickness of the casting and the temperature of the metal. Most of the possible defects that can occur are a result of the solidification process. If some of the molten metal cools too quickly, the part may exhibit shrinkage, cracks, or incomplete sections. Preventative measures can be taken in designing both the part and the mold and will be explored in later sections.

Removal - After the predetermined solidification time has passed, the sand mold can simply be broken, and the casting removed. This step, sometimes called shakeout, is typically performed by a vibrating machine that shakes the sand and casting out of the flask. Once removed, the casting will likely have some sand and oxide layers adhered to the surface. Shot blasting is sometimes used to remove any remaining sand, especially from internal surfaces, and reduce the surface roughness.

Trimming - During cooling, the material from the channels in the mold solidifies attached to the part. This excess material must be trimmed from the casting either manually via cutting or sawing, or using a trimming press. The time required to trim the excess material can be estimated from the size of the casting's envelope. A larger casting will require a longer trimming time. The scrap material that results from this trimming is either discarded or reused in the sand casting process. However, the scrap material may need to be reconditioned to the proper chemical composition before it can be combined with non-recycled metal and reused.

Read More